Test Knitting

Early in 2024, I decided that I wanted to try test knitting. I thought it would be a fun way to get free patterns, interact with pattern designers directly, network with other test knitters on social media, and get my name out there. I have really enjoyed test knitting, but every project has had its own set of fun and challenges.

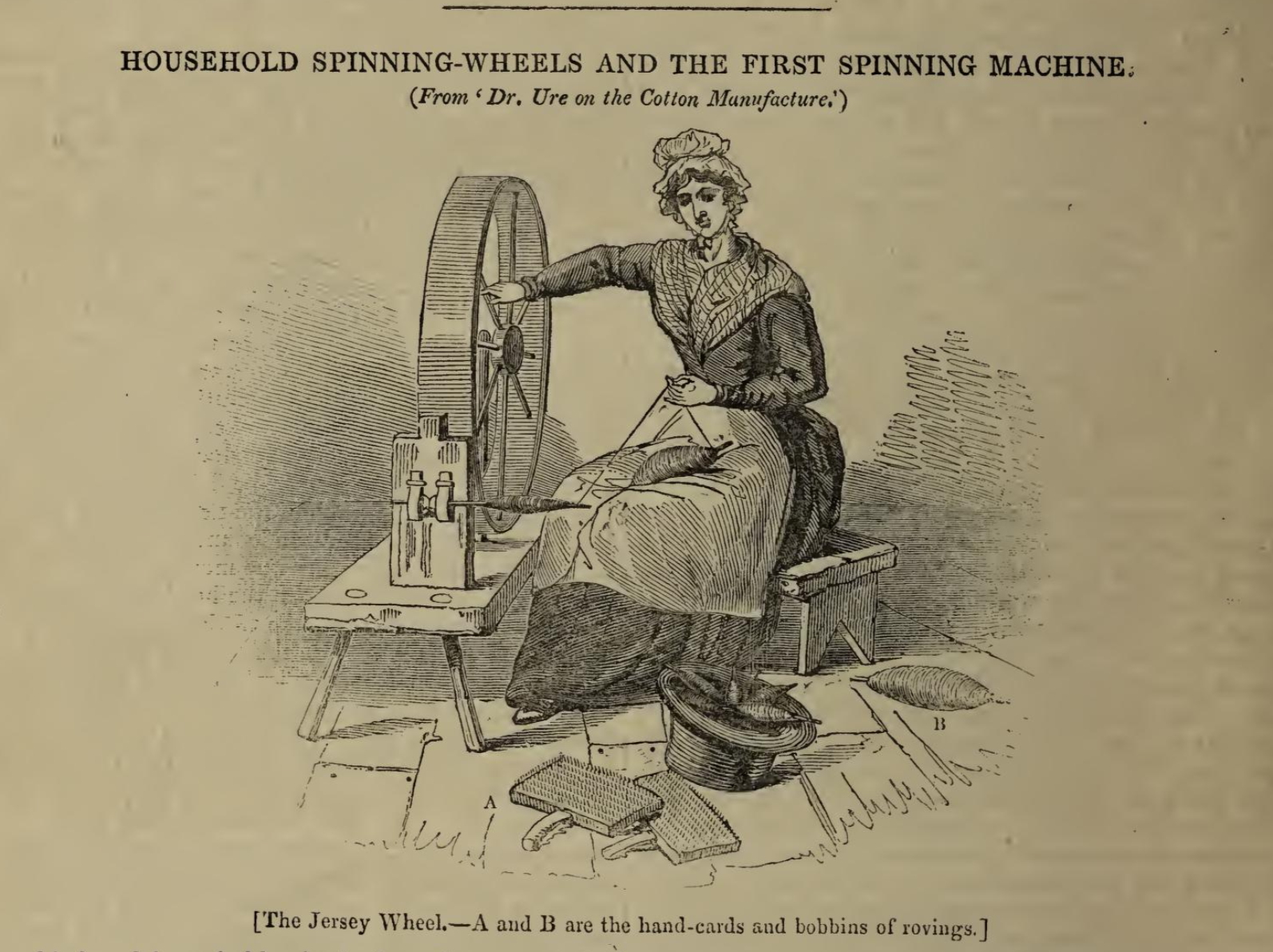

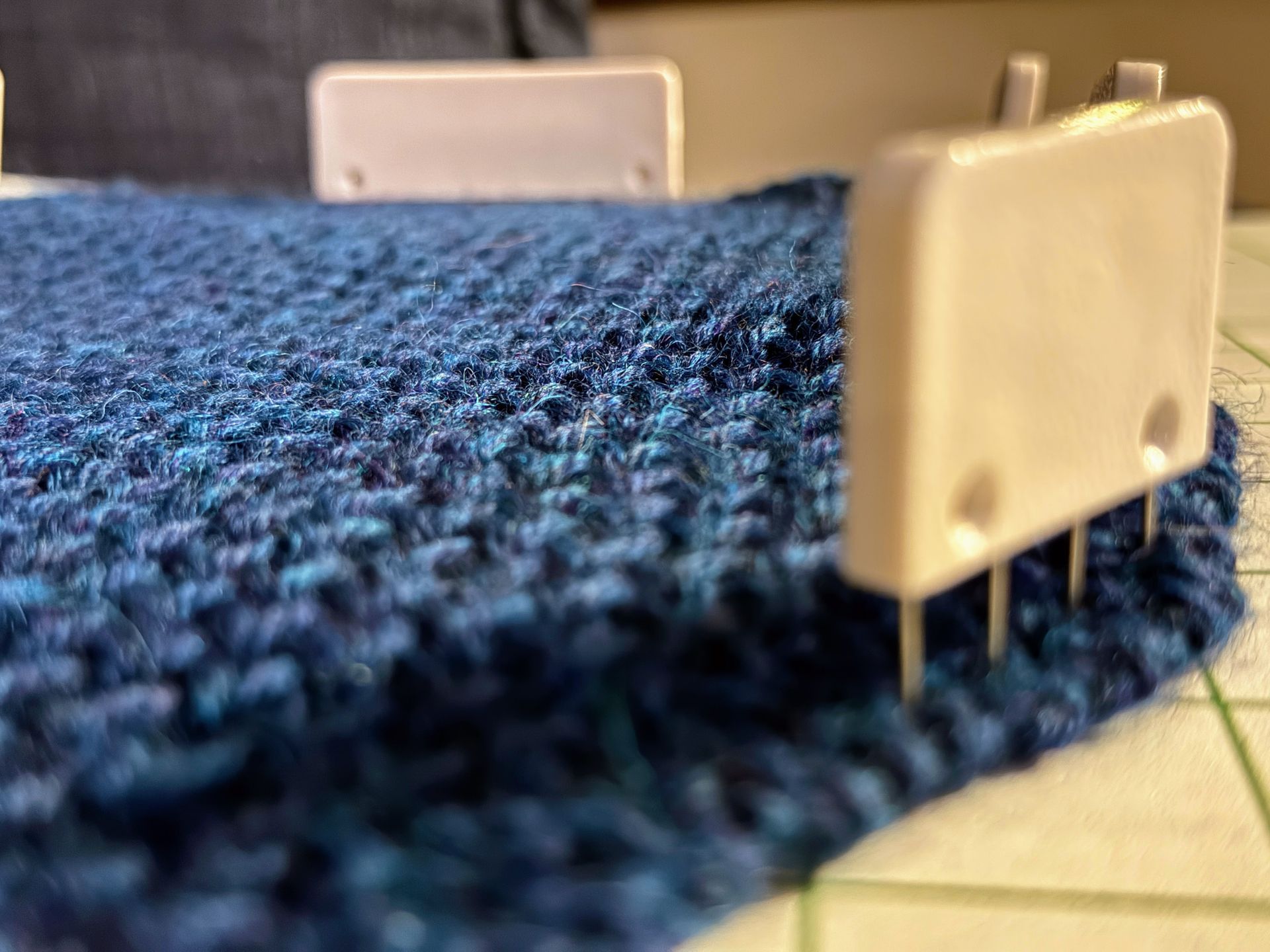

Deep Dive Bandana Cowl

Maren Odenthal (knitterista)

This was my first test knit and Maren set the bar very high. She provided a PDF of her knitting pattern, including some sample images. Her instructions were very easy to follow and I learned several new techniques, including honeycomb brioche and the icelandic bind off. There ended up being just one or two revisions to the pattern after testing, but when I read the instructions and something seemed off, I thought it was my mistake.

I used Knit Pick's Wool of the Andes in Sapphire Heather. While I loved the color and knitting with the yarn, the resulting texture was far too scratchy for me to wear next to the skin. I would definitely reknit this pattern in a softer wool so that I can wear this lovely design during the cold and wet Pacific Northwest winters.

Woodhaven Pullover

Tif Nielan

Link on Ravelry

This project was only my second sweater project as well as my second test knit. Tif had several revisions and updates through the process due to the numerous sizes and the complication of the project. However, the initial PDF was very clear, and again, I noticed no issues during my knitting with the pattern.

I also used Knit Pick's Wool of the Andes in Sapphire Heather and Mist.

And somehow, I still have never taken a decent full sweater picture of this project. Partially, because my tension/gauge ended up a bit small, which makes it difficult for me to wear a shirt underneath. Again, because I'm sensitive to the Wool of the Andes, this sweater is not comfortable to wear next to the skin.

Stitches Sweater

Kutovakika

If I begin to sound like a broken record, I'm sorry. This is another test knit where I made a bad yarn choice and missed up my gauge. Veronica projected the pattern through a google docs file, allowing all testers to input thoughts and suggestions as they worked through the pattern. There was a lot of collaboration and networking, which was really fun!

The stitches sweater is a fun colorwork sweater that would be perfect to wear to your next crafting meet up. However, I used Lion Brand's Fisherman Wool as my main color, with Knit Pick's Wool of the Andes in Sapphire Heather and Mist, as well as a handspun merino blend for my colors. My tension was too tight again, resulting in a sweater that was several sizes too small. The sweater is unfortunately tightest around my bust, not just due to my larger circumference but due to the colorwork limiting stretch.

The sweater is constructed with a circular yoke, worked in the round, then sleeves, and the collar stitches is picked up at the end. With the tightness of my tension and the lightness of my handspun yarn, it is difficult to read the word "stitches" when it's on. I blocked it after completing the color work section in hopes that it would fit (it didn't), but I decided to complete the body and sleeves regardless to finish out the text knit.

I never finished the last sleeve because I was not sure that I would ever really wear this sweater. I guess I'm holding out some hope that I might fit into it better some day, at least with a shirt under it, so the wool is not as itchy.

Future Test Knits?

After three text knit projects in two months, I decided to take a break over the summer to work on projects I wanted to do. However, I do plan on working on future text knits. In fact, I recently signed up for one that is semi secret, so make sure you check back often here, or on my Instagram at @needle_wheel_loom for updates!